Cutting and Bending of Section Steel

- List of Our Services

- Cutting and Bending of Section Steel

Have you experienced any problems as follows?

- You would like to shortening the lead times.

- You would like to receive parts so that you can assemble them immediately after receiving them.

- You would like to cut cost by reducing the cost of in-land transportation.

Cutting and bending of section steel

to mitigate a customers' work load

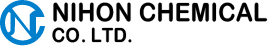

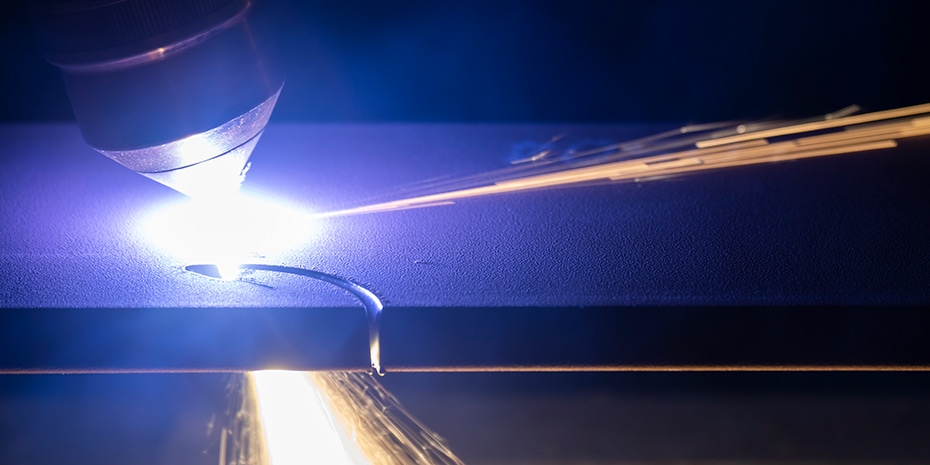

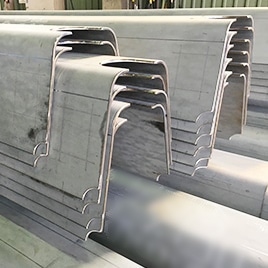

Based on customers' drawings, the marking, cutting, piercing, bending and beveling of steel materials are conducted. Nihon Chemical is capable of flat steel and mold steel cutting and 6-axis robotic (automatic marking & cutting machine), bending using press benders and beveling. By combining these processes with the manual gas cutting of complicated shapes and steel bending for skewed curved shapes, a variety of products can be produced for ships, bridges and transportation equipment. We will carefully finish surfaces after cutting by using a grinder or by chamfering, so that the customers' workload in the subsequent processes will be reduced. Integrated processing from shot primer application is also possible.

Our Works

-

Side longitudinal (jumbo valve)

for commercial ships -

Bottom longitudinal (unequal leg and thickness angles [NAB])

for commercial ships -

H-section steel for transportation equipment

-

T-longitudinal cutting

-

T-longitudinal bending for Company O

-

NAB bending for Company M

-

Valve plate bending for Company K

-

U-rib for bridges